In today's Furniture Design And Production System, the use of software for production is a norm. Efficient and intelligent software allows front-end distributors and back-end factories to optimize and control the manufacturing process, production efficiency and production costs. It can be said that without software, there would be no furniture industry that is developing rapidly.

But at present, software is still uneven in the market. What is the most needed software in the furniture industry?

For Furniture Design System Suppliers, the service content for consumers is mainly designed scene display and sales quotation. Especially in recent years, the development momentum of customization is very good, because the customization of furniture is to cater to the individual needs of consumers, which is often very different from the finished furniture. Therefore, it is particularly important to show design solutions to consumers.

In addition to presenting the design plan to consumers for confirmation, it is also necessary to present the design plan to the back-end factory for manufacturing. Therefore, data and process manufacturing requirements are very important to the design plan. The factory needs to transform these data and process requirements into operating instructions for production equipment and process flow, as well as production management such as kneading orders, in order to optimize production costs and production efficiency, and produce the highest quality products.

Furniture Industry Software

Obviously, what the dealer needs most is the software that can perfectly present the design plan, and what the factory needs most is the software that can operate the equipment efficiently and intelligently. The connection between the plan and the device data is a crucial link in the middle. Once there is a problem with the production materials during the docking process, the products that consumers need cannot be produced. Therefore, the industry is now calling for front and back integration of software, but many claim that real front and back integration cannot be achieved through software at the front and back ends.

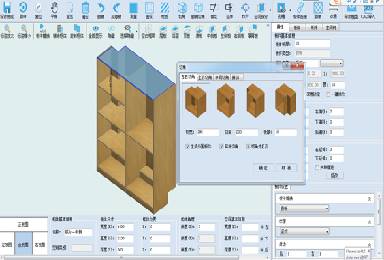

The reason is that in the production of design plans, most of the Furniture Industry Software on the market often uses the spelling method in the customization diagram to achieve personalized product customization design, and fix the original products in the product In the library. Cabinets, components, etc. are put together, and this connection is very limited in design. Once the consumer's customized needs exceed the usual range, it will not be able to meet the consumer's needs. Moreover, this spelling will also cause too much accumulation of similar data in the product library, which will not be flexible and fast in future use.

In addition, these software usually only do front-end design or back-end segmentation. When the front end and the back end are connected separately, only certain functions or devices can be connected. It is impossible to do these two things at the same time. The effect of front and back integration will be greatly reduced.

The front-end part should be designed with a complete front and back integration software. In addition to being able to play, it should also be able to paint to meet various personalized customization needs. In the back-end production part, it should be possible to easily convert various front-end production data into operating instructions for different production equipment to ensure smooth and correct connections between the front and back ends.

In the era of Industry 4.0, software can also be said to determine the survival of furniture companies. Front and rear integration is the goal and direction of software innovation, but there is still a long way to go to truly realize Front and rear integration.

Leave a message

Copyright © Qingdao Haixun Soft Engineering Co., Ltd. All Rights Reserved| Sitemap